Introduction

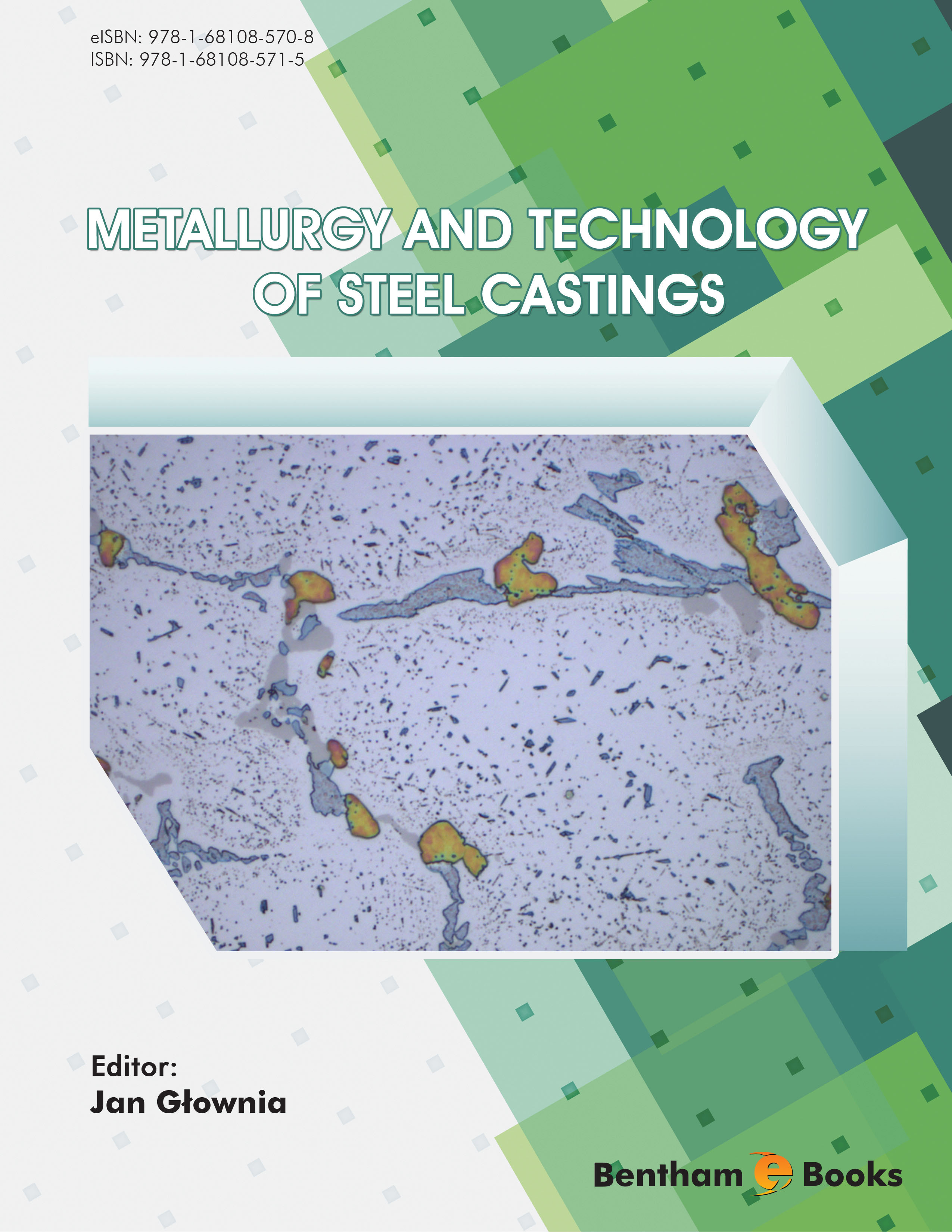

Metallurgy and Technology of Steel Castings

is a comprehensive textbook for students and professional engineers in the field of foundry engineering and materials science. The topics covered in this book explain the association between the quality of liquid metal and the properties of the finished cast. Readers will learn about the thermodynamic conditions for addition and recovery of chemical elements (such as Cr, Ni and Mo) in steel, degasifying processes, the influence of alloying additives for manufacturing steel castings that operate in extreme temperatures (minus temperatures, heat resistance conditions, anti-corrosive cast steels) and basic cast conditions for making the castings (pouring, feeding and heat treatment systems).

Metallurgy and Technology of Steel Castings

gives readers essential information about steel and steel cast manufacturing processes and equips them with the knowledge to overcome the challenges faced in the foundry environment.