The problems related to the greenhouse effect and the scarcity of fossil hydrocarbons – the reservoirs of which will reduce dramatically during this century – impose a conscious use of energy in each of the three major sectors of energy consumptions (industry, transport and domestic uses) which roughly adsorb one third of the global demand. In 30 years from now the increase of the world population and of the average standards of life will cause a non-sustainable explosion of the energy demand, if current energy-intensive technologies will not be phased out.

The availability of cheap and performing electrolyte membranes, the heart of fuel cells, would drastically increase the efficiency in the use of fossil fuels and facilitate a wider diffusion of renewable energies through the so-called hydrogen economy. As of today, the 15% of the energy produced worldwide is employed for separation processes, and most of them are inefficient. Membrane operations are needed to reduce not only production costs but also equipment size, energy utilization and waste generation, in other words they are powerful tools for process intensification. Seawater desalination is a successful example: since membrane operations in integrated systems are 10 times more energetically efficient than thermal options, they represent the cheapest and less polluting solution for the supply of freshwater in desert and remote areas.

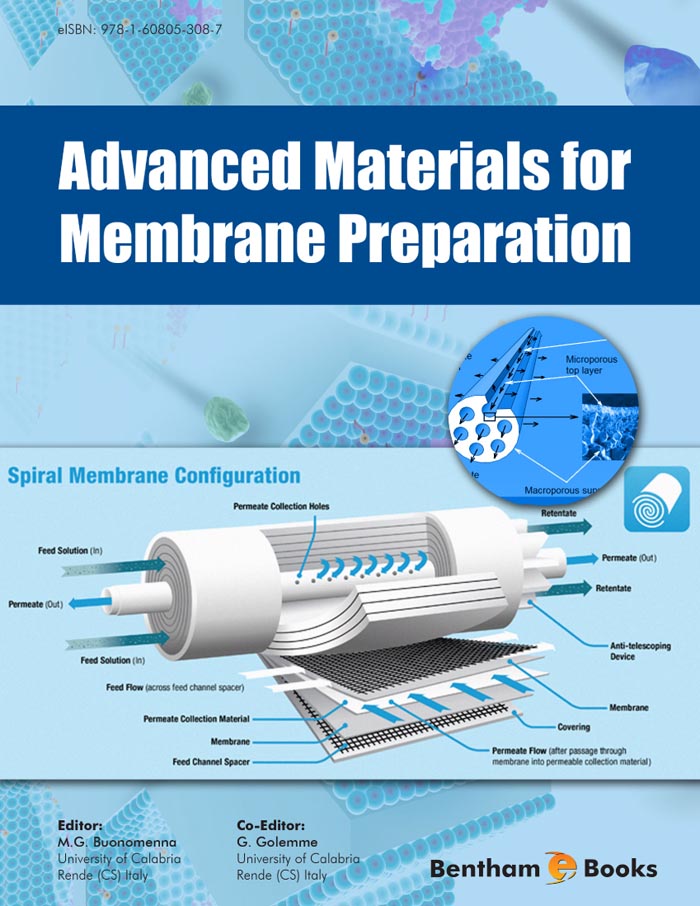

The early polymers used for the preparation of reverse osmosis and gas separation membranes (i.e. cellulose acetate and polysulfone) can treat moist streams or aqueous solutions, but cannot tolerate organic solvents, high temperatures and aggressive chemicals, and are unfit to operate in the harsh environments typical of the oil refining and the chemical industry. For this reason new tough materials are sought in order to expand as much as possible the province of membrane operations. The preparation of tailored synthetic membranes and their utilization on a large industrial scale are a recent development which has gained a substantial importance due to the large number of practical applications.

Today, membranes separate liquids, gases and vapours, recover valuable compounds, separate, purify and concentrate juices, milk, serum, broths in the agro-food and drug industries, and they are key components in energy conversion systems.

The modern membranes used in the various applications differ widely in their structure and function and the way they are operated in the different membrane processes. Therefore, several excellent books focus on certain aspects of membrane science such as the theoretical treatment of transport, engineering aspects of membrane process design, membrane preparation and large scale production. This book provides to scientists and students a short but reasonably comprehensive overview of the most recent research strategies for the design of membranes based on advanced materials for specific applications.

Chapters written by experts will make the reader acquainted with a variety of topics ranging from new membrane materials (inorganic oxides for gas separation, zeolites, metal organic frameworks, perovskites for oxygen production, carbon nanotubes, mixed matrix membranes, ionomers for fuel cells, perfluoropolymers, block copolymers) to processes (membrane reactors, aqueous and solvent resistant nanofiltration, pervaporation) to simulation tools of transport of molecules in carbon nanotubes and membranes for fuel cells.

The goal of the authors is to offer an up-to-date understanding of the materials science of membranes in various applications and of its present and future technical relevance.

Maria Giovanna Buonomenna

Giovanni Golemme

University of Calabria

Rende (CS) Italy